Automotive Components Diagnostic and Repairing Skills

Programme Overview

Automotive Components Diagnostic and Repairing Skills

This skills programme is designed to provide a comprehensive foundation in the mechanical and technical aspects of vehicle repair. It covers the full spectrum of automotive systems, from foundational hand tool mastery and materials science to the complex diagnostics of drive trains, braking, and fluid power systems (Hydraulics and Pneumatics).

This unit standard is for individuals in the automotive engineering industry who diagnose and repair main automotive components according to workplace procedures and manufacturer manuals. Competency includes interpreting job instructions, preparing and conducting tests, diagnosing and repairing faults, applying safety procedures, and completing necessary documentation. Learners are expected to work autonomously on components from systems such as electrical, engine, drivetrain, brakes, hydraulics, and pneumatics. Prerequisite skills include the ability to work safely, dismantle, repair, and assemble automotive components at NQF Level 3. Recognition of prior learning is assumed in these areas. The unit standard ensures comprehensive competence in automotive repair tasks.

Core Learning Units

The programme is divided into eight specialized chapters:

- Hand Tools and Their Applications: Selection, safety, and correct usage of specialized automotive tools.

- Engineering Materials and Metallurgy: Understanding the properties of metals and alloys used in vehicle manufacturing.

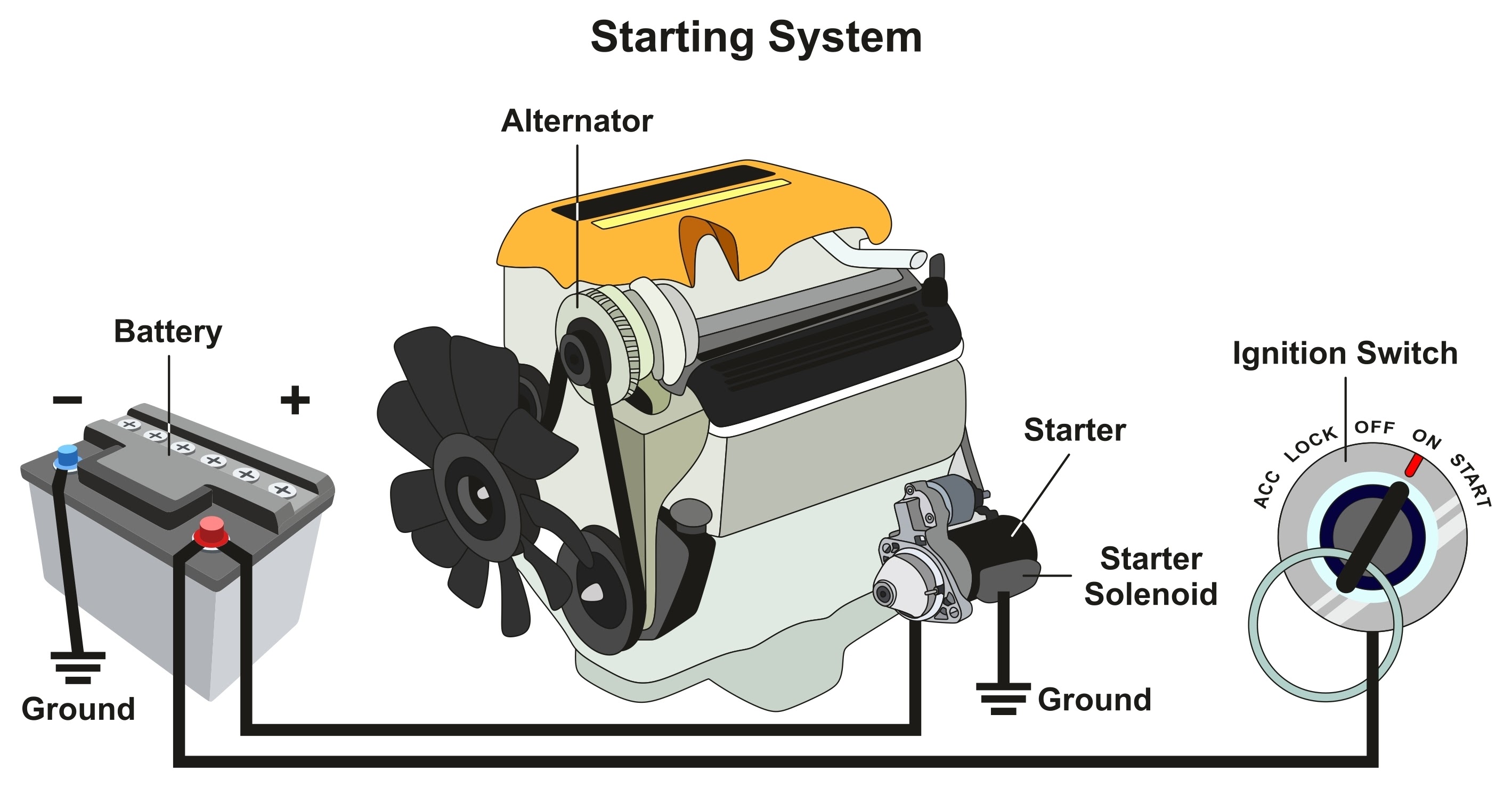

- Basic Auto Electrical and Electronics: Fundamentals of circuitry, battery maintenance, and electronic components.

- Engine Maintenance and Tune-Up: Practical procedures for preventative engine care and performance optimization.

- Drive Train Mechanics: Diagnostics and repair of clutches, gearboxes, and drive shafts.

- Brake Systems: Comprehensive training on hydraulic and mechanical braking components.

- Hydraulic Systems: Mastery of fluid power systems used in heavy machinery and light vehicles.

- Pneumatic Systems and Specialized Tools: Training in compressed air systems and high-end pneumatic shop tools.

Duration

4 to 6 months

Qualification

Skills Programme (NQF Level 2/3 Aligned)

Entry Requirements

Requirements

To enroll in this skills programme, the following are typically required:

- Academic: Minimum of NQF Level 1 (Grade 9) with a pass in Mathematics. A basic understanding of Physical Science is highly recommended for the metallurgy and electrical units.

- Language: Proficiency in English for reading technical manuals and activity guides.

- Physical: Good manual dexterity and the ability to distinguish colored wiring.

- Workplace Placement: Access to an accredited workshop to complete the practical activities outlined in the Activity Guide.

Career Outcomes

Potential Career Paths:

Career Outcomes

Graduates are prepared for specialized technical roles in various automotive environments:

- Automotive Diagnostic Assistant: Specializing in identifying mechanical and electronic faults.

- Brake and Clutch Specialist: Working in dedicated repair centers focusing on safety systems.

- Junior Mechanic / Assistant: Providing comprehensive support in general repair workshops.

- Fluid Power Technician: Focusing on hydraulic and pneumatic system maintenance for heavy vehicles.

Interested in this Programme?

Need Help Deciding?

- Free consultation

- merSETA funding support

- Career guidance

- Facility tours available